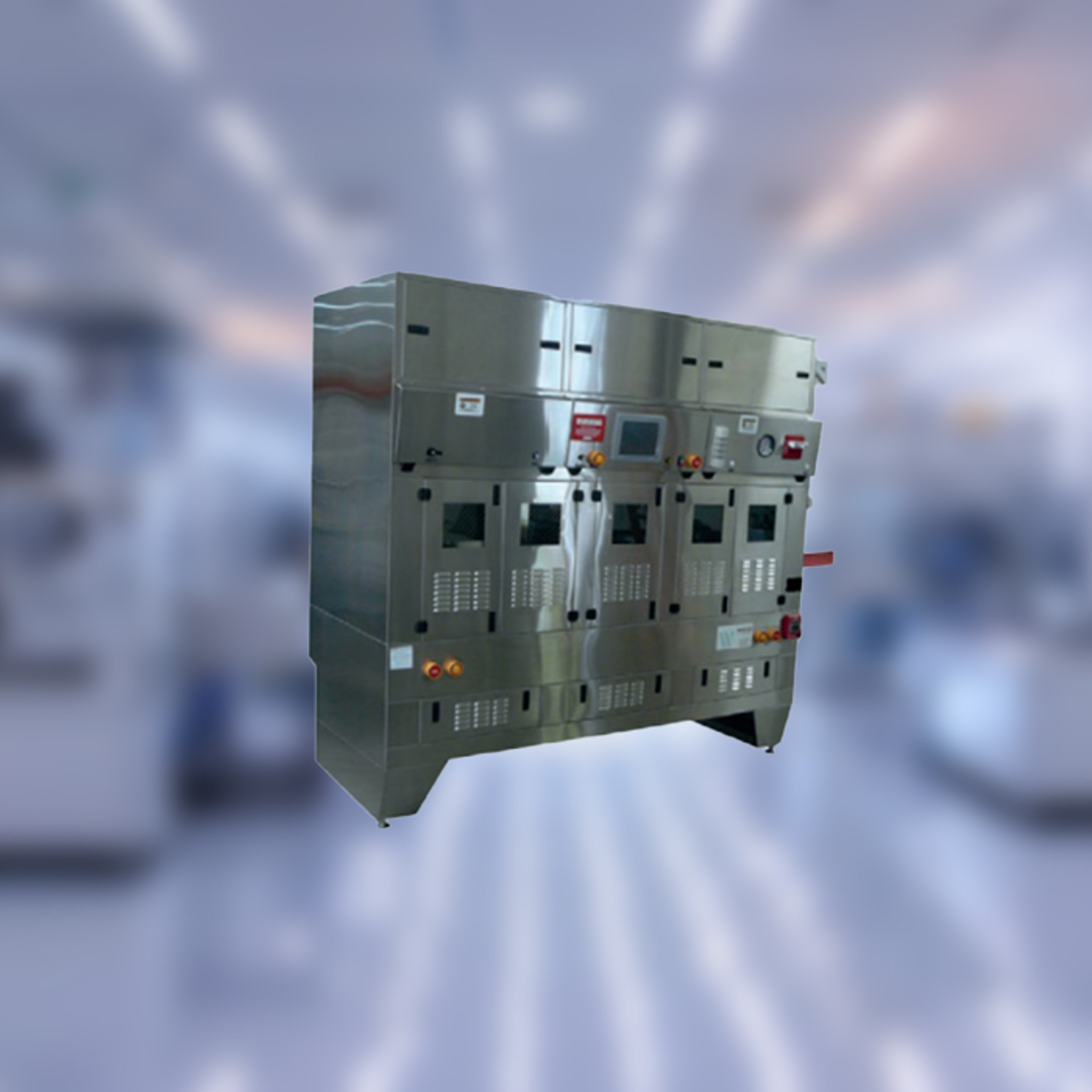

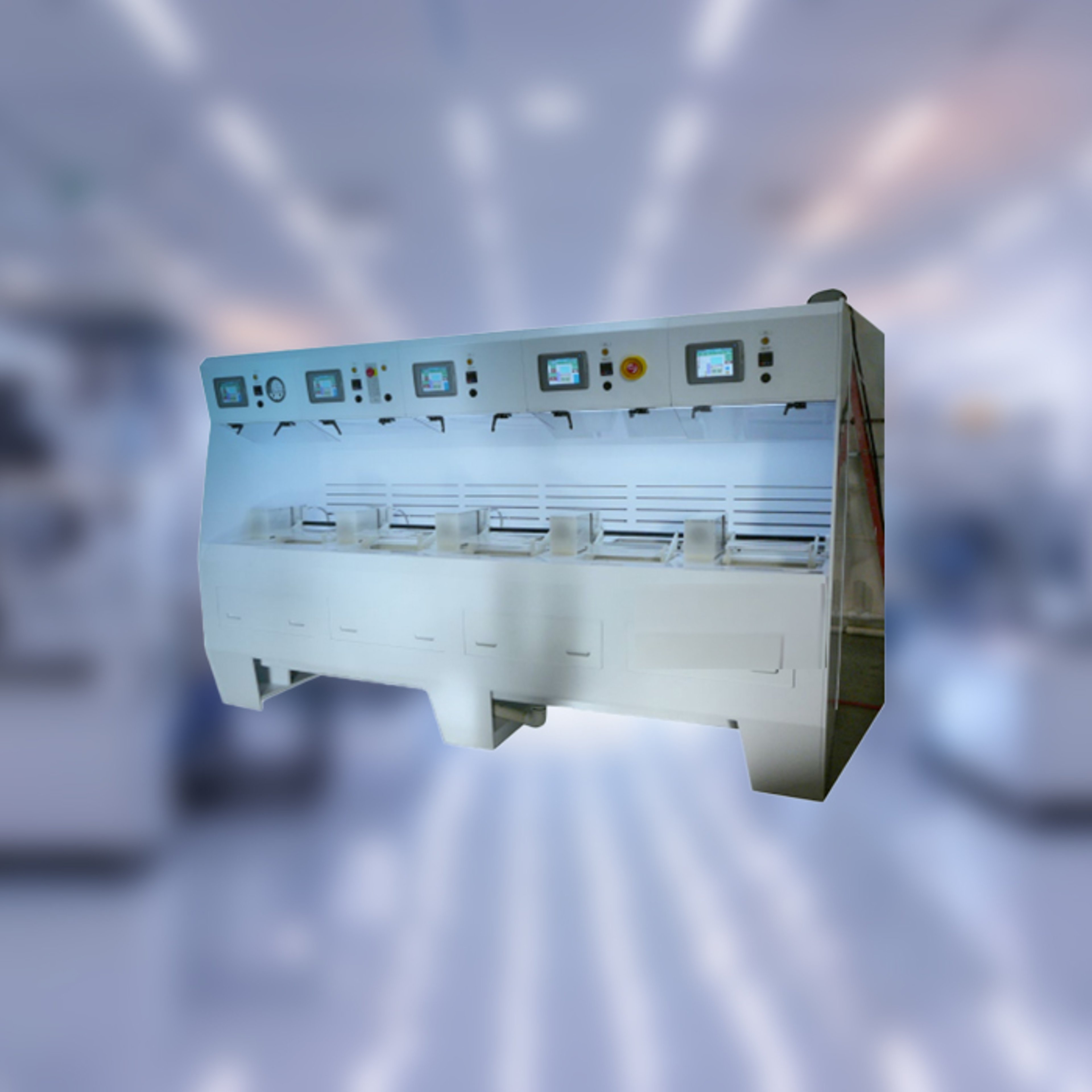

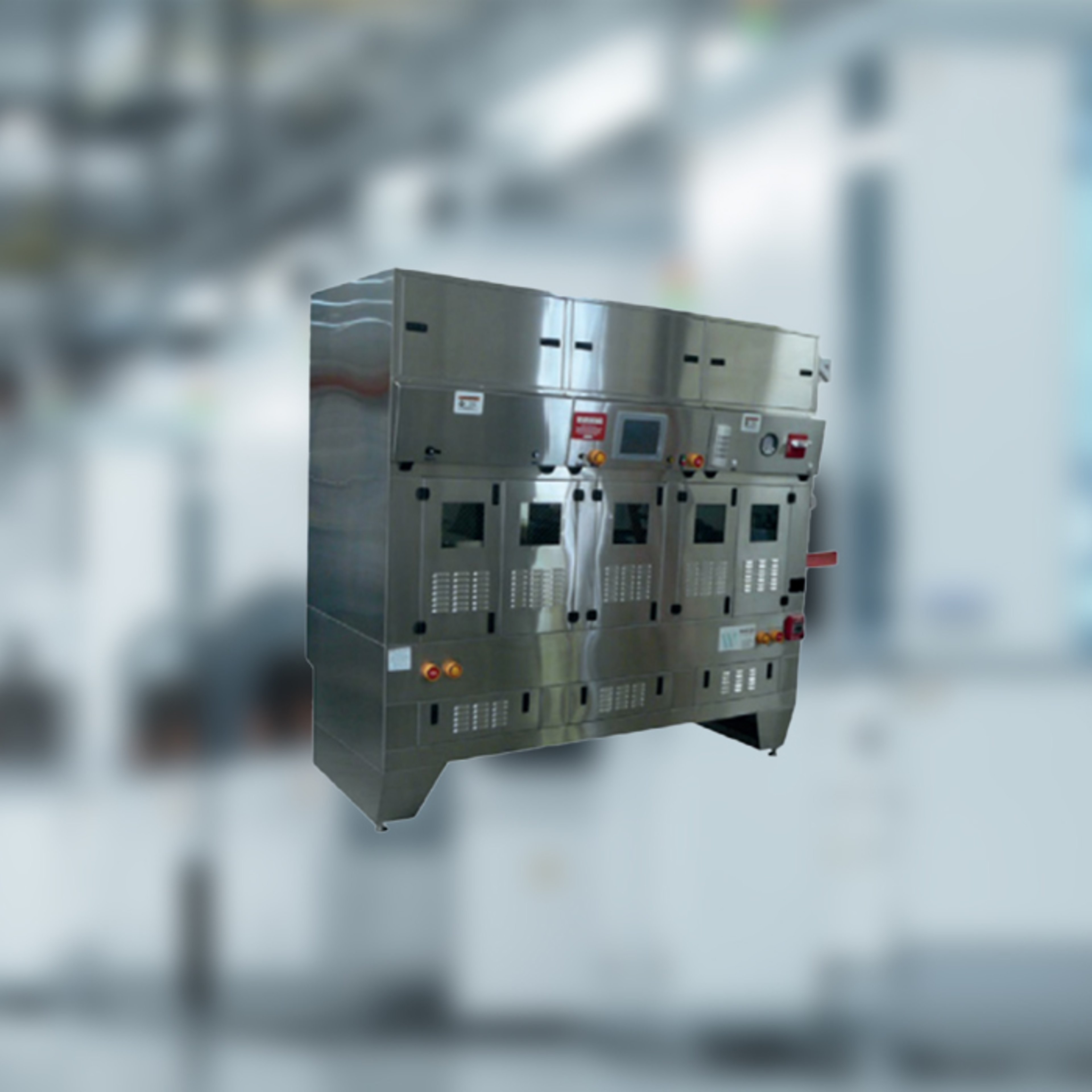

Specialist wet bench manufacturing

The spectrum of Exentec surface preparation tools and wet benches ranges from batch immersion to spray or single-wafer application wet benches. All wet benches can be configured from manual to fully automated multitasking systems.

Our wet benches are designed for repeatability and volume, with an emphasis on processes with two or more processing tanks. Built to current SEMI standards, our wet process stations are available in fully automated, semi-automated and manual configurations.

- FEOL, BEOL, Packaging modules, Advance Packaging modules, MEMS Pattern Plating, Magnetic Deposition, Electro-Etch, and E-less Deposition

- Cleaning, resist strips, etching, development, metal lift-off, IPA recovery and drying

- Usable for acid, base and solvent applications

- Single or multi-cassette bath sizes

- Silicon wafers from 100mm to 450mm, III-V materials, photomasks, glass and large manifolds

- Customized substrates

Wet Bench products by Exentec

Exentec's Wet Bench products are engineered to prepare silicon wafer surfaces, support cleanroom manufacturing steps, perform etching processes, and return large fabrication components to a contaminant‑free condition: