MEGA Filtration Systems

Modular, standalone slurry filtration systems engineered for continuous, low- to high-volume process filtration

Modular slurry filtration systems

The MEGA® SF Series Filtration Systems are modular, standalone slurry filtration systems engineered for continuous, Low to high-volume process filtration. Ideal for semiconductor fabs, CMP applications, and other high-tech manufacturing environments, the SF Series supports full loop integration or Point-of-Use (POU) tool filtration with unmatched reliability and flexibility.

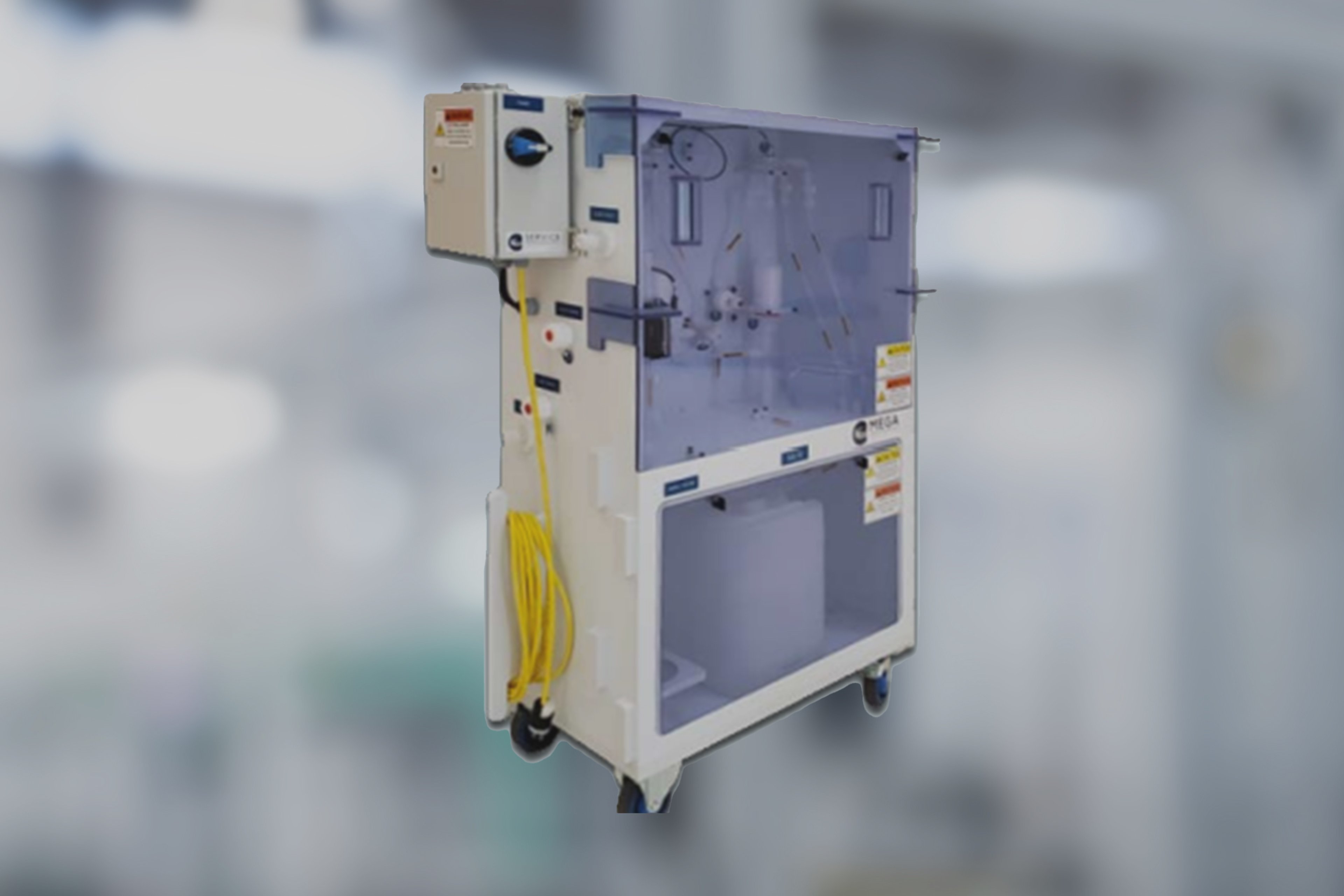

The MEGA® Filter Cart is a mobile slurry filtration unit designed for R&D environments, pilot lines, and localized Point-of-Use tool filtration. With its flexible cartridge or capsule format, it supports both temporary and long-term slurry filtration requirements.

Filter Cart Overview

Filter Cart Overview

- Supports 2–3 parallel filter banks with 20" filter bowl/head assemblies

- Optional cabinet configuration with 10" bowl/head assemblies

- Auto flush and purge for each bank to maintain flow integrity

- Automatic de-airing and pre-press functions for seamless transitions

- Differential pressure detection, alarms, and monitoring

- Degassing capabilities to reduce bubble contamination

- Designed for control via SBD or CBD unit

MEGA® Filter Cart benefits

MEGA® Filter Cart benefits

- Portable and compact design for easy mobility and tool integration

- Flexible filter media options: supports standard cartridges or capsules

- Sample ports for both input and output, ideal for process development

- Built-in safety with pressure monitoring, flow meters, and wheel locking

- Perfect for R&D or temporary deployment in full-production fabs

- Quick setup and minimal space requirements

MEGA® Filter Cart options

MEGA® Filter Cart options

- Individual controls to allow retrofits or additions to existing systems

- Cartridge or capsule support with customizable bowl sizes or spacers

- Multiple bank configurations available (Single, Dual Series, Dual Parallel

- Automated flush and purge of system

- Automated degassing

Key benefits of the MEGA® SF series

Key benefits of the MEGA® SF series

- Uninterrupted Filtration Multiple parallel filter banks ensure continuous slurry flow during filter change-outs and system flushes

- Modular & Configurable Supports series and/or parallel filtration setups, enabling scalable integration across production lines or R&D labs

- Compact Footprint Space-saving design fits easily into cleanroom and fab environments, including cabinet-style versions for tighter areas

- Redundancy & Bypass Support Maintains global loop flow during maintenance or filter replacement, preventing process downtime

MEGA® SF series suitable applications

MEGA® SF series suitable applications

- Semiconductor manufacturing

- Post-CMP slurry filtration

- Solar and photovoltaic (PV) production

- LED manufacturing

- Silicon Carbide (SiC) and IoT device processing

- Low-solids CMP processes

- Advanced materials R&D

Filter Cart Overview

Filter Cart Overview

- Supports 2–3 parallel filter banks with 20" filter bowl/head assemblies

- Optional cabinet configuration with 10" bowl/head assemblies

- Auto flush and purge for each bank to maintain flow integrity

- Automatic de-airing and pre-press functions for seamless transitions

- Differential pressure detection, alarms, and monitoring

- Degassing capabilities to reduce bubble contamination

- Designed for control via SBD or CBD unit

MEGA® Filter Cart benefits

MEGA® Filter Cart benefits

- Portable and compact design for easy mobility and tool integration

- Flexible filter media options: supports standard cartridges or capsules

- Sample ports for both input and output, ideal for process development

- Built-in safety with pressure monitoring, flow meters, and wheel locking

- Perfect for R&D or temporary deployment in full-production fabs

- Quick setup and minimal space requirements

MEGA® Filter Cart options

MEGA® Filter Cart options

- Individual controls to allow retrofits or additions to existing systems

- Cartridge or capsule support with customizable bowl sizes or spacers

- Multiple bank configurations available (Single, Dual Series, Dual Parallel

- Automated flush and purge of system

- Automated degassing

Key benefits of the MEGA® SF series

Key benefits of the MEGA® SF series

- Uninterrupted Filtration Multiple parallel filter banks ensure continuous slurry flow during filter change-outs and system flushes

- Modular & Configurable Supports series and/or parallel filtration setups, enabling scalable integration across production lines or R&D labs

- Compact Footprint Space-saving design fits easily into cleanroom and fab environments, including cabinet-style versions for tighter areas

- Redundancy & Bypass Support Maintains global loop flow during maintenance or filter replacement, preventing process downtime

MEGA® SF series suitable applications

MEGA® SF series suitable applications

- Semiconductor manufacturing

- Post-CMP slurry filtration

- Solar and photovoltaic (PV) production

- LED manufacturing

- Silicon Carbide (SiC) and IoT device processing

- Low-solids CMP processes

- Advanced materials R&D

Filter Cart Overview

Filter Cart Overview

- Supports 2–3 parallel filter banks with 20" filter bowl/head assemblies

- Optional cabinet configuration with 10" bowl/head assemblies

- Auto flush and purge for each bank to maintain flow integrity

- Automatic de-airing and pre-press functions for seamless transitions

- Differential pressure detection, alarms, and monitoring

- Degassing capabilities to reduce bubble contamination

- Designed for control via SBD or CBD unit

MEGA® Filter Cart benefits

MEGA® Filter Cart benefits

- Portable and compact design for easy mobility and tool integration

- Flexible filter media options: supports standard cartridges or capsules

- Sample ports for both input and output, ideal for process development

- Built-in safety with pressure monitoring, flow meters, and wheel locking

- Perfect for R&D or temporary deployment in full-production fabs

- Quick setup and minimal space requirements

MEGA® Filter Cart options

MEGA® Filter Cart options

- Individual controls to allow retrofits or additions to existing systems

- Cartridge or capsule support with customizable bowl sizes or spacers

- Multiple bank configurations available (Single, Dual Series, Dual Parallel

- Automated flush and purge of system

- Automated degassing