Raised floor finishes

Exentec offers a wide range of floor finishes for aluminium raised floor systems:

- PVC or Caoutchouc

- Single and double component epoxy coating

- Conductive or non-conductive

Exentec also provides coating for GMP suitable floor:

- PVC or Caoutchouc

- Ceramic or stone ware

- Single and double component epoxy coating

- Pharma Terrazzo

- Conductive or non-conductive

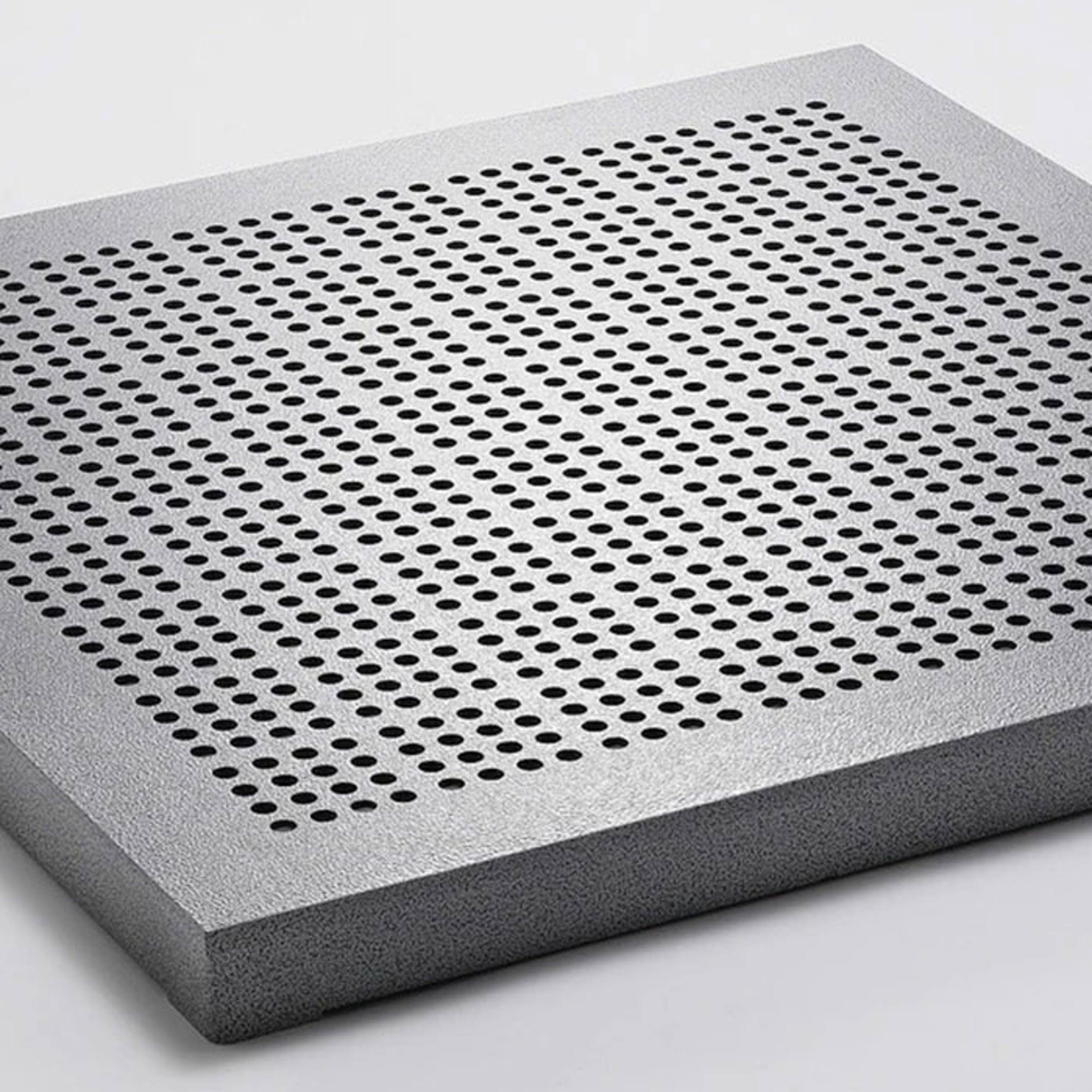

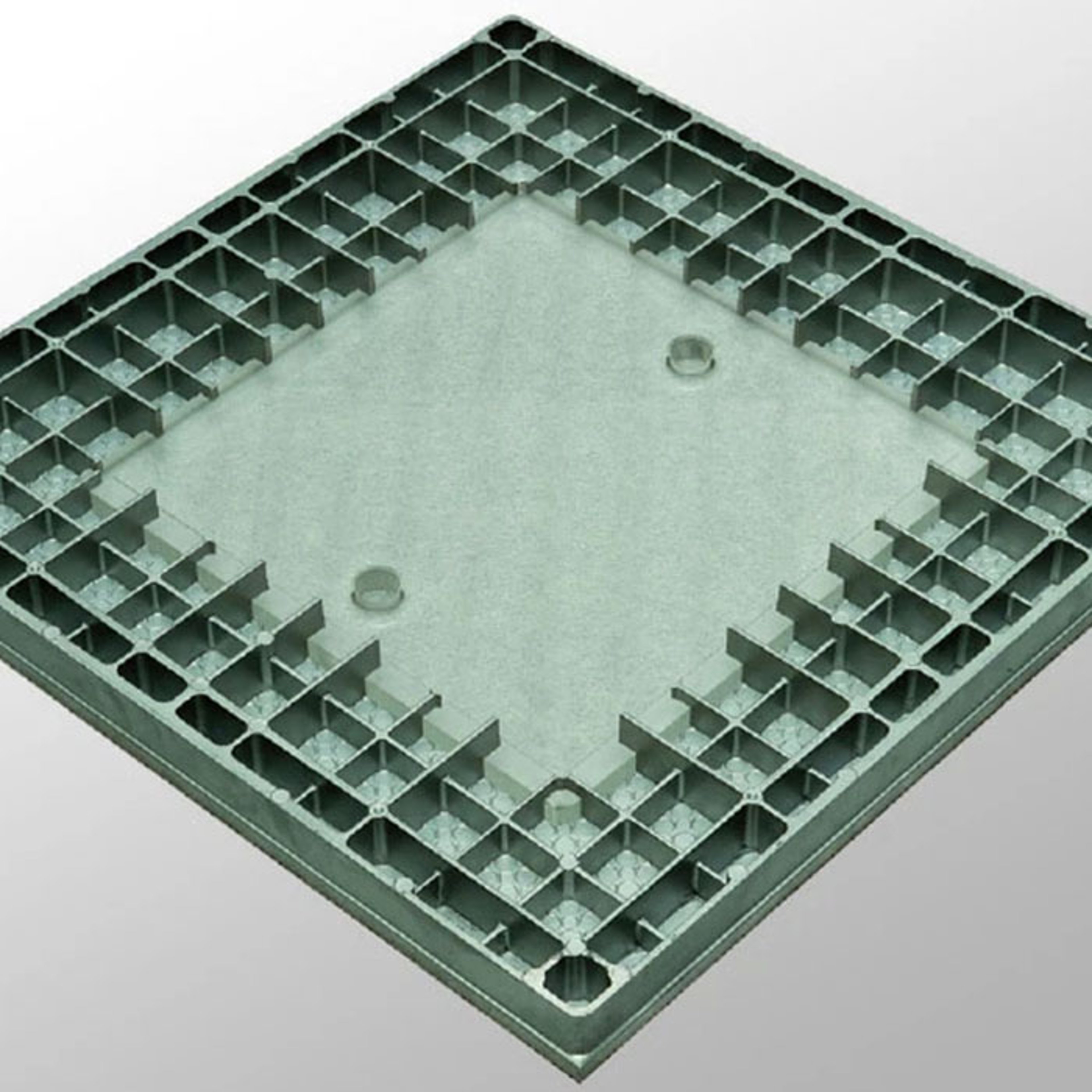

Dampers for raised floor panels

Perforated and grid panels can be fitted with Dampers. This delivers even air distribution throughout the cleanroom or around workstations and production tools. All panel types can be fitted with an acrylic cover, allowing quick and convenient access to equipment located under the raised floor.

Raised floor substructure

Pedestals

Exentec's pedestals are compatible with solid, perforated and grating panels. They are available for all seismic environments with an axial load performance of 5,000-11,000kg. Finishes include bare aluminium, e-coat or epoxy powder coat. The pedestals are available in a module size of 600 mm.

Pedestal types are dependent on seismic zone, finished floor height and floor loading conditions. Aluminium pedestals can be used in applications where a non-ferrous material is required. For other applications a mixed aluminium/ steel solution can be used. These have an aluminium head with steel stud and tube to work with a steel base plate assembly. These are designed for highly seismic locations, high floor heights and heavy loading. The aluminium and aluminium / steel pedestals can be mixed in the same flooring without affecting the panels.

Stringers

Exentec's aluminium Stringers are made with extruded aluminium and designed to fit 600mm systems. The Stringers are used to provide lateral support only and are not intended to improve the vertical load carrying capacity of the panels. They will conform to the size of the panels. When used in cleanrooms, the Stringers can feature an e-coat, epoxy powder coat or bare finish (steel stringers excluded). Both conductive and non-conductive coatings are available.

Bracing

The substructure can be braced (particularly along perimeter lines) with additional bars or threaded rods. These are clamped onto the base at an angle and mechanically fastened to the slab by anchor bolts. Movement is inhibited when the floor has to cope with high horizontal loads. Seismic bracing of the floor system can be installed for heavily loaded areas such as tool move-in paths, heavy machine areas and seismic activity regions.

Spanning

When installations beneath the raised floor such as pipes, air ducts or other utility lines are in conflict with the standard pedestal layout, the spanning system can help to stay

within the standard layout. C-Channels on the pedestal heads bridge these obstructions.