Chemical Offload

Chemical Offload

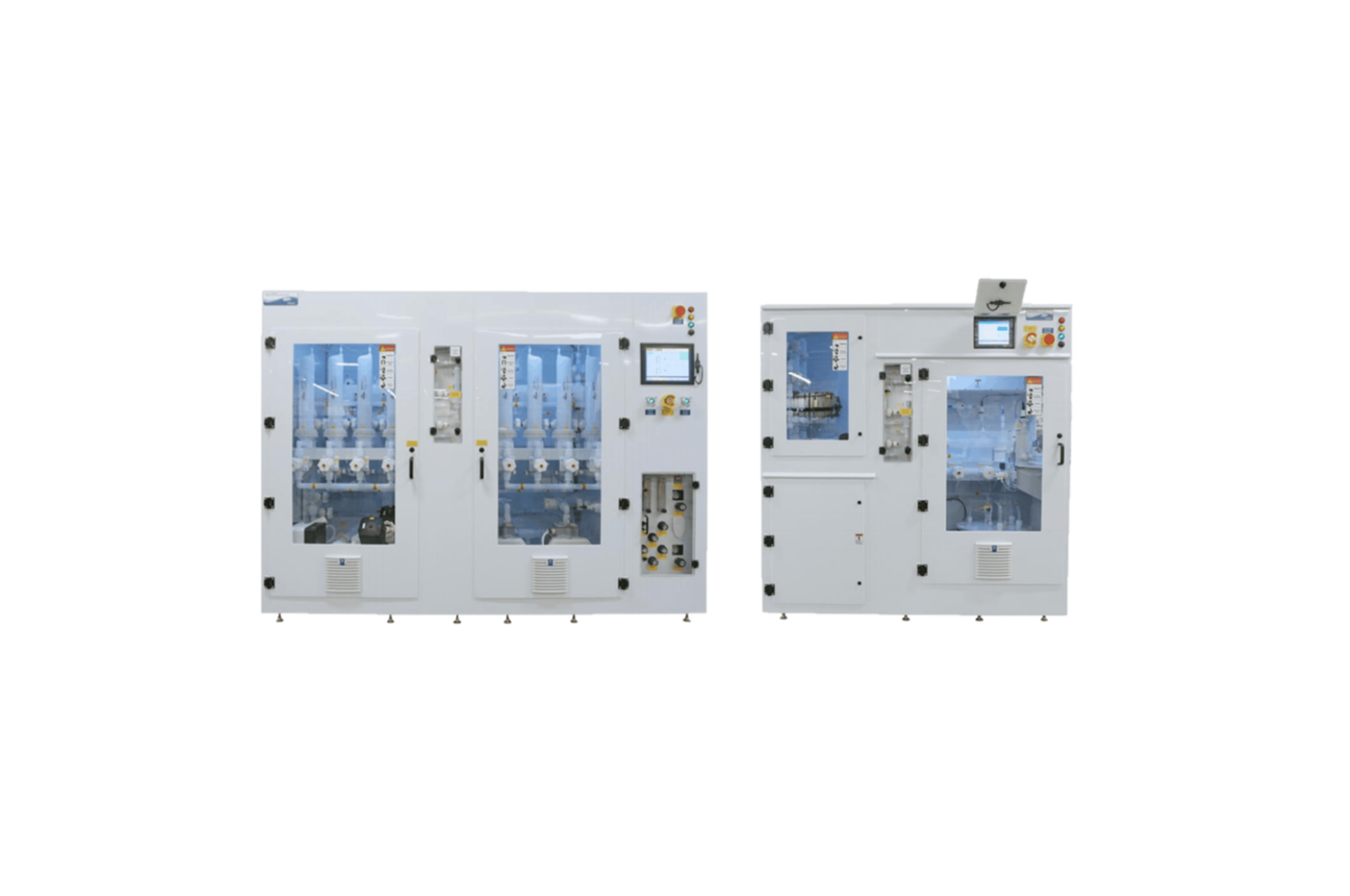

Titan™ Transfer and Offload Bulk Chemical Distribution System

The Exentec Titan™ Transfer and Offload System automatically transfers an aqueous chemical from the tanker to the bulk distribution tanks. This system monitors the level of the bulk tanks and allows tanker offload into storage tank A. Storage tank A refills tank B at the defined setpoint, and chemical transfers for production tools come from storage tank B; which can be configured to alternate with tank A for full redundancy.

Benefits:

- Fully automated systems with advanced instrument monitoring and control

- Low cost of ownership

- Flexible and user-friendly HMIs

- Space efficient designs

- Continuous transfer of chemical from the main tanks to production distribution tanks

- System and/or component redundancy to maximize production uptime

- Monitors and controls:

- Tanker offload functionality

- Tank levels during offloads and normal operation

Features:

- Flow and pressure monitoring

- Quality Control verification of incoming chemical

- Automated sampling for offload analytical verifications

- Maintenance points for system purging and draining

- All wetted flow paths are PFA, PTFM, or PTFE

- Polypropylene cabinet materials

Our fluid management systems are designed to increase process windows, improve process yields, optimize floor space, minimize downtime and lower overall operations costs.

High Purity Chemical Systems

We offer equipment, field support service and technical expertise to meet various application needs of high purity fluid delivery, chemical blending and state-of-the-art CMP slurry systems for semiconductor manufacturing and other high-tech industries.

Chemical Offload

The Exentec Titan™ Transfer and Offload System automatically transfers an aqueous chemical from the tanker offload cabinet to the main distribution tanks.

Chemical Distribution

Exentec offers equipment, support service and technical expertise to meet application needs in the design and manufacturing of high and low purity chemical distribution systems.

In-Line Blending

Exentec's patented on-demand in-line chemical blending and supply of chemical solutions technology can accommodate on-demand dynamic change in flow rates by the end users or points of use while maintaining precise blend accuracy.

Chemical Generation

Exentec's NH4OH on-site chemical generation technology helps semiconductor fabs to significantly reduce their overall chemical supply costs, improve resiliency and increase ecological sustainability.