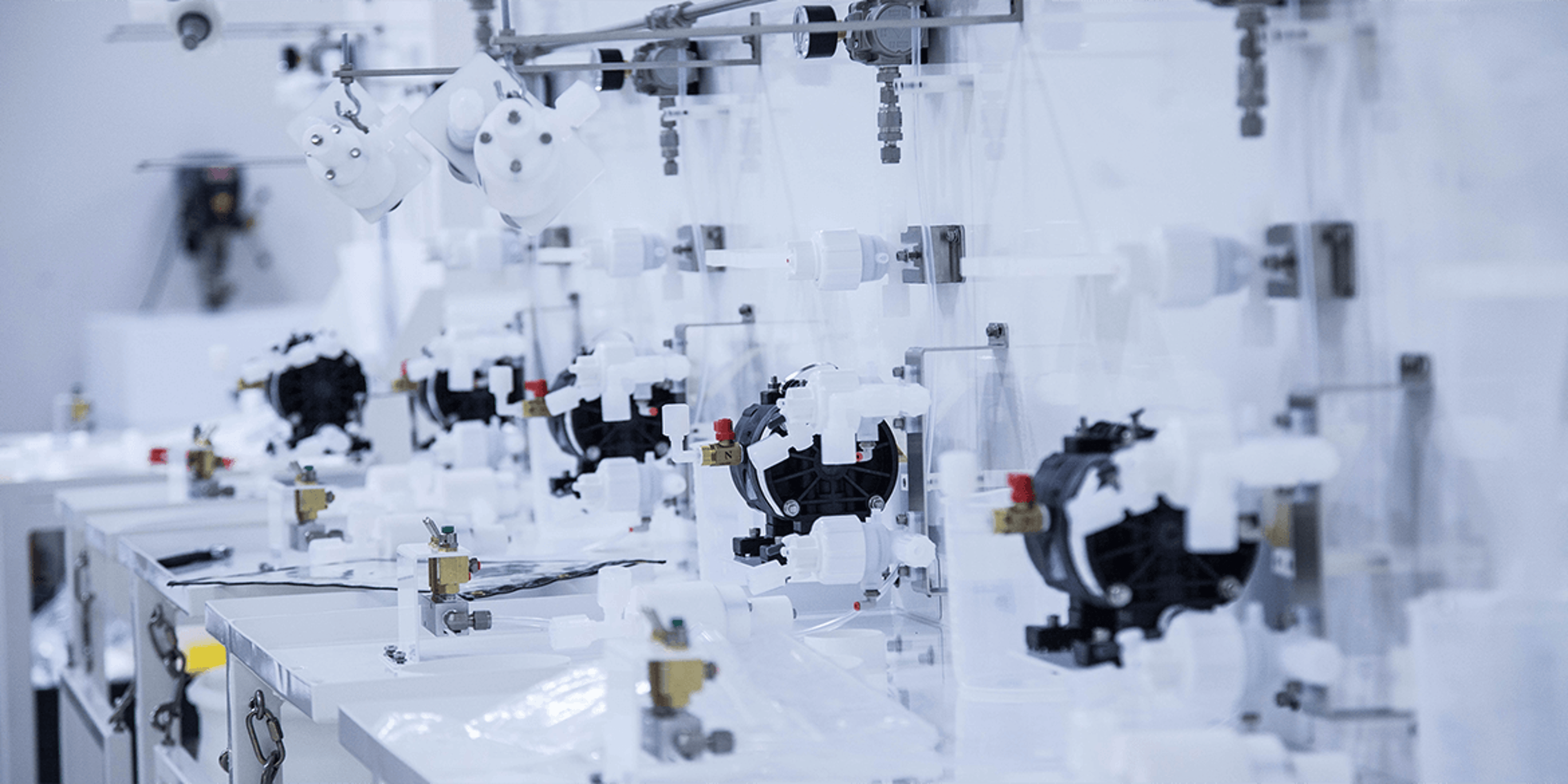

Exentec specializes in ultra-high purity chemical and gas systems for the semiconductor industry. Our portfolio includes blending and delivery equipment for a wide range of applications in aqueous chemicals and CMP slurries.

In addition, we provide the required field support services, controls, integration, and technical expertise to meet stringent semiconductor process control needs.

Our reliable systems offer:

- Advanced metrology-driven closed loop process control

- Automated chemical and slurry quality control

- Flexible, scalable and precise delivery and blending systems

- Increased process control via blend concentration and pressure control

- Seamless integration into SCADA with full I&C support

- Optimal floor space

- Maximum uptime

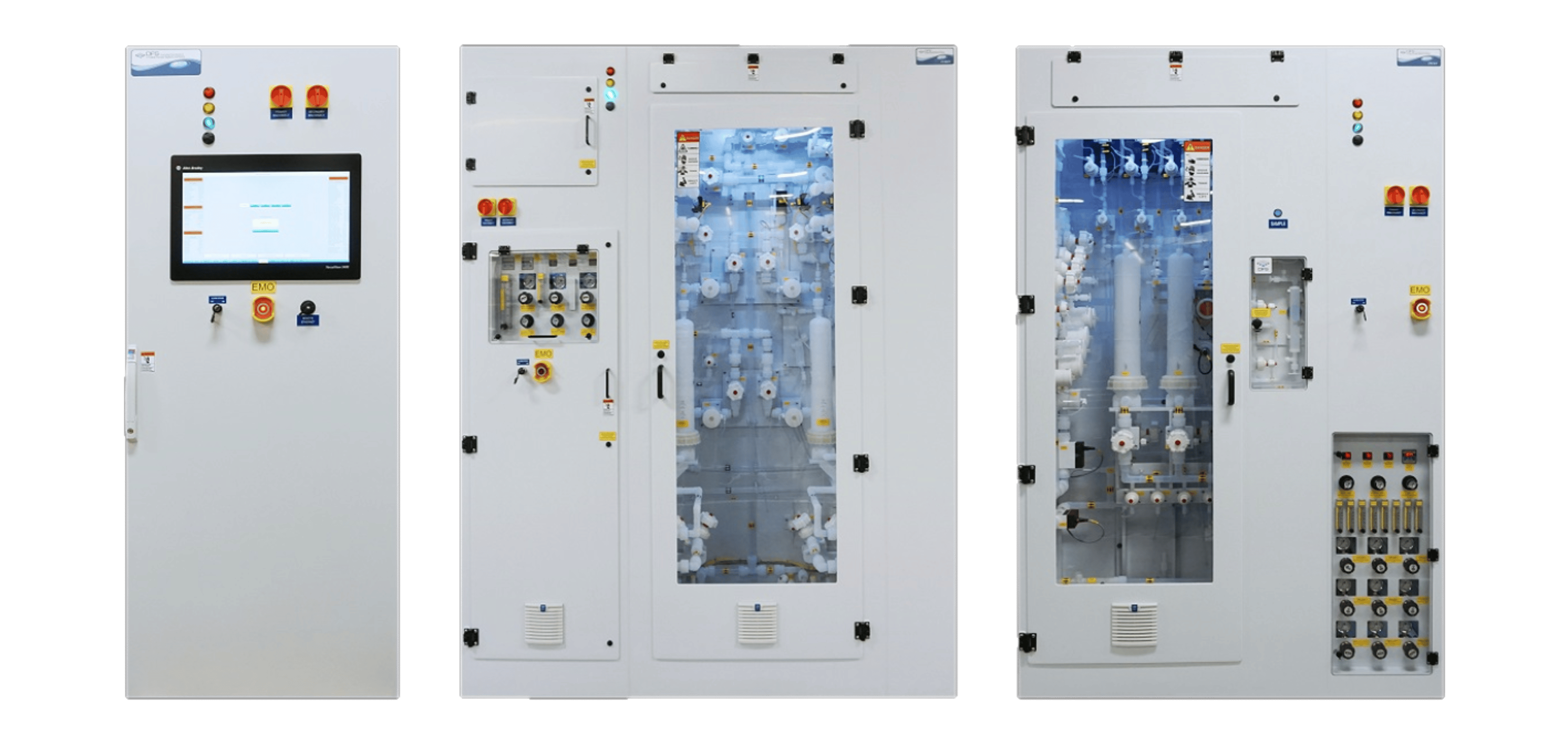

High Purity Chemical Systems

Exentec offers equipment, field support service and technical expertise to meet various application needs of high purity fluid delivery, chemical blending and state-of-the-art CMP slurry systems for semiconductor manufacturing and other high-tech industries.

Chemical Offload

Providing continuous transfer of chemical from the main tanks to production distribution tanks with system and/or component redundancy to maximize production uptime.

Chemical Distribution

Our chemical distribution systems improve processes, optimize floor space, minimize downtime and extend product life, lowering overall cost of ownership.

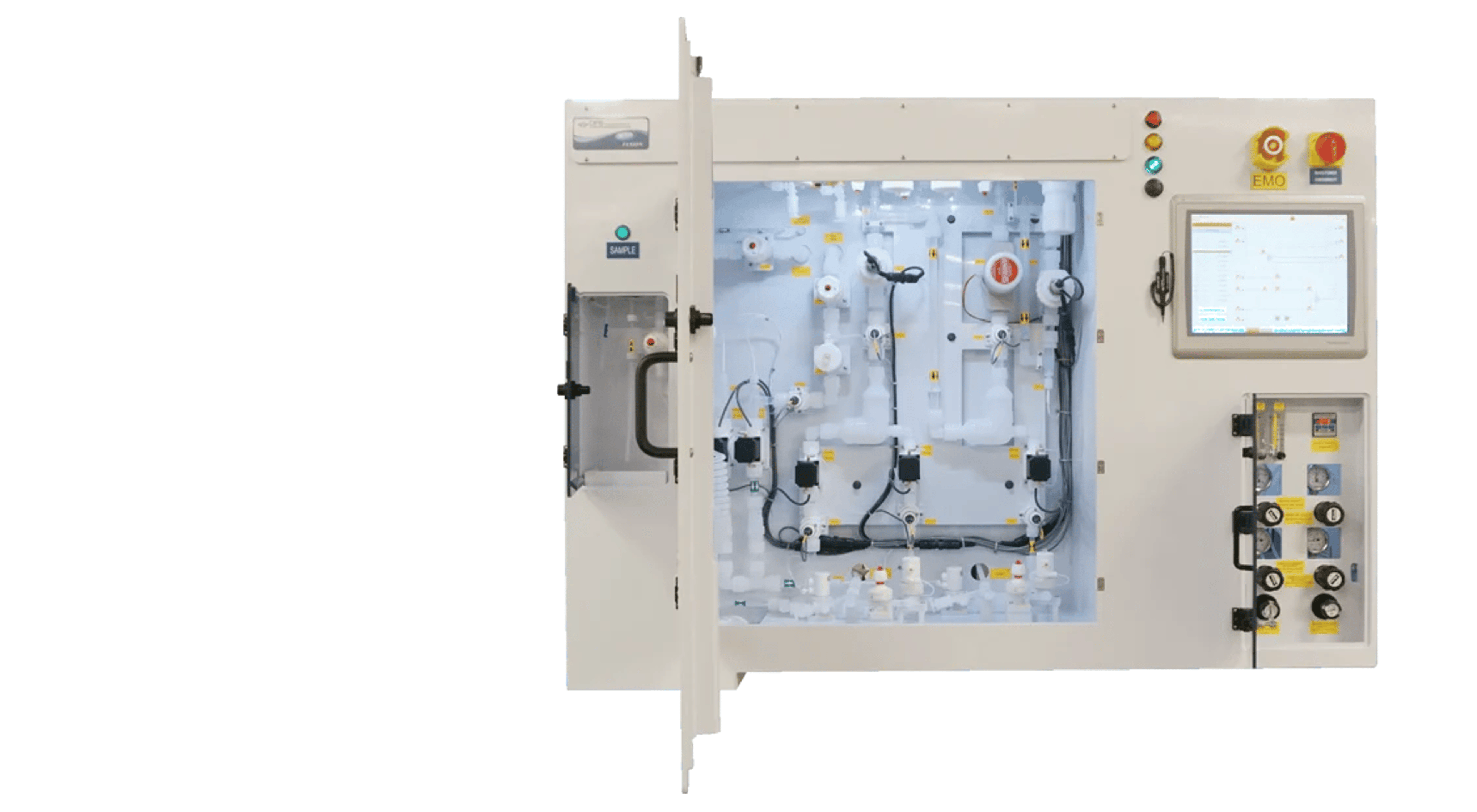

In-line Blending

Exentec’s patented on-demand in-line chemical blending and supply of chemical solutions technology accounts for on-demand dynamic change in flow rates by the end-users or points-of-use while maintaining precise blend accuracy.

Chemical Generation

With Exentec’s integrated NH4OH on-site chemical generation technology, semiconductor fabs can significantly reduce their overall chemical supply costs, increase quality, harden resiliency against supply-chain disruptions, and improve ecological sustainability.

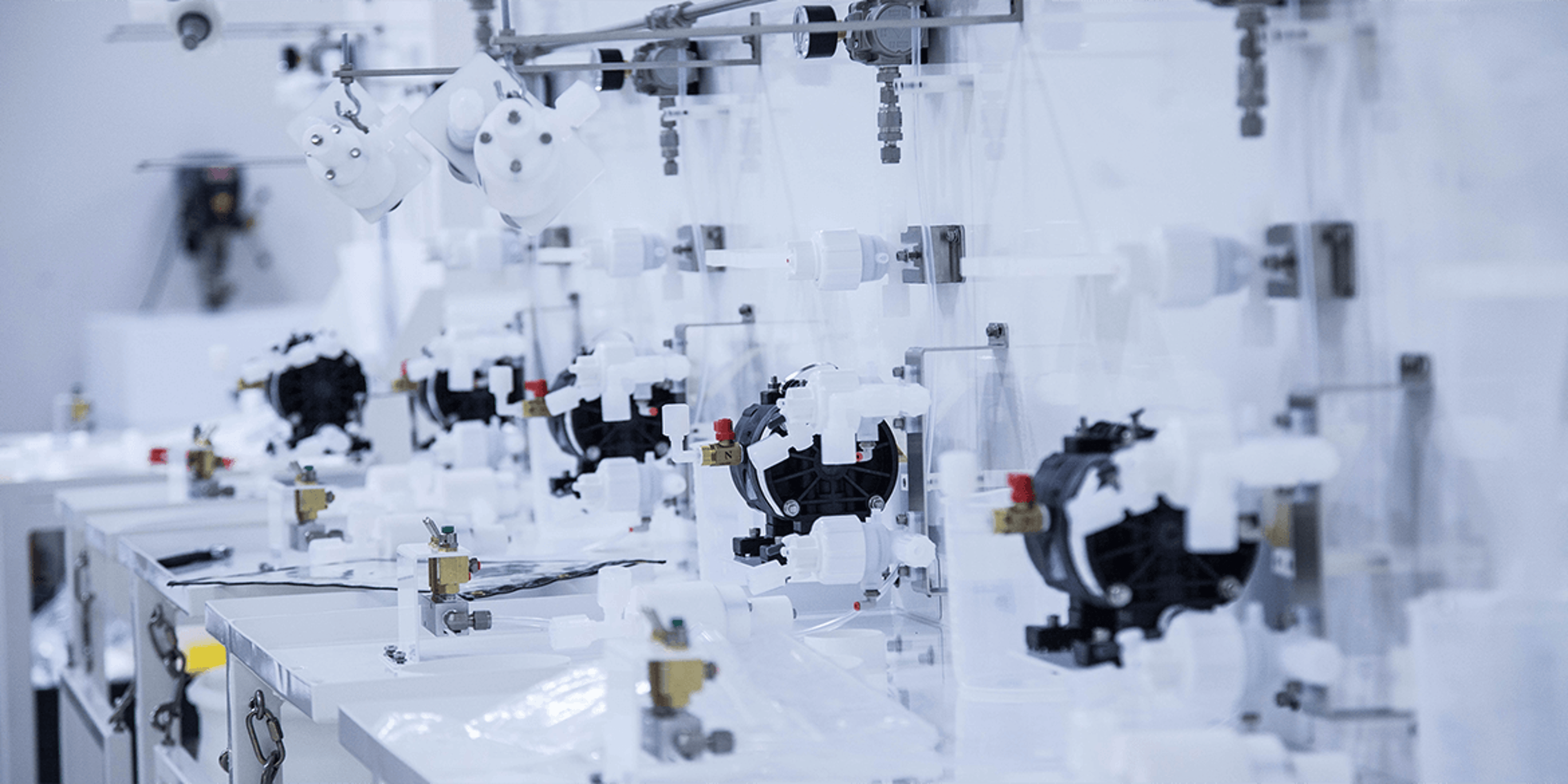

CMP Slurry Blending & Delivery

Remove expensive labor-intensive offline metrologies and manual process adjustments. Exentec has successfully developed onboard control technology that allows for closed-loop control of a customer-specific semiconductor CMP slurry solution in blend and distribution operations.

Cleanroom

Superior solutions and comprehensive services

We develop, produce and maintain reliable cleanroom products and production environments for ultra-clean controlled atmospheres.

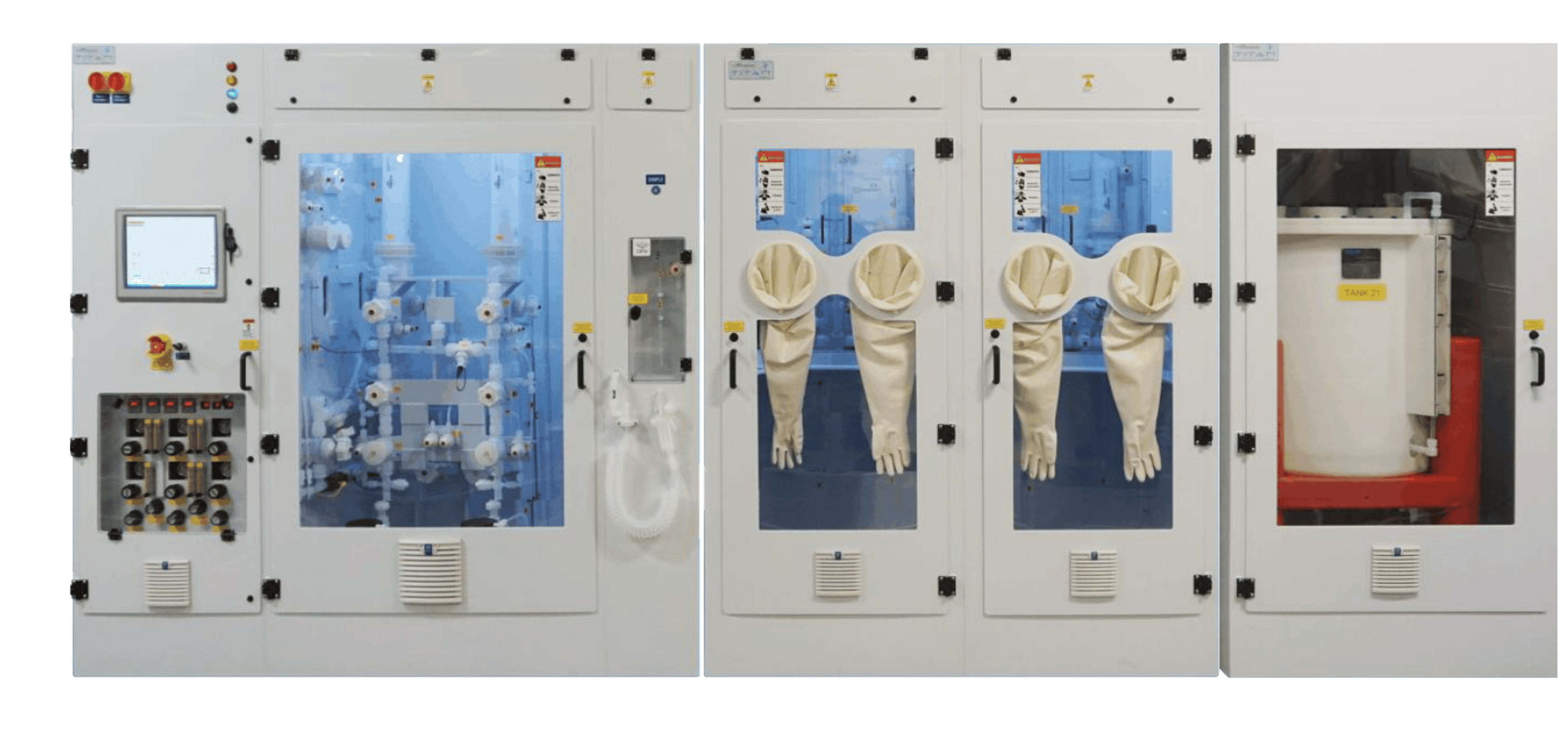

Mini Environments

In the battery market, Exentec pioneers a unique modular Mini Environment concept, integrating energy reduction and technological improvements.

Air Handling Units

Air Handling Units from Exentec are distinguished by energy-efficient design. Our research and development team works with state-of-the art equipment and always contributes the latest knowledge.

Critical Subsystems and Controlled Environments

Pure media supply systems for sensitive products

Chemical Supply

Ultra-high purity chemical & slurry blending and distribution systems

Ultra-high purity chemical & slurry blending and distribution systems

Ampoules and Sensors

We manufacture liquid level sensors, pyrophoric chemical handling and DOT 4B ampoules, cylinders and canisters widely used in the semiconductor, photovoltaic and battery industries.

Process Exhaust

We set the industry standard for safe and reliable corrosive fume exhaust duct systems

Gas Abatement

We are a supplier of choice for major semiconductor companies around the world, providing Point-of-Use (POU) gas abatement solutions for deposition, etch and diffusion process tools.

Wet Bench

Exentec's Wet Bench products seamlessly align application requirements with equipment performance. We specialize in designing surface preparation systems

Exentec's Wet Bench products seamlessly align application requirements with equipment performance. We specialize in designing surface preparation systems

Slurry Systems

Exentec Slurry Systems are trusted worldwide for their critical role in advanced chemical mechanical planarization (CMP) processes