Exentec provides complete design, delivery, installation and maintenance of high-quality air handling units for the treatment of make-up or re-circulation air.

Commonly handling air volumes between 1,000 and 200,000 cm/h. Our Air Handling Units treat air for Particulate and Airborne Molecular Contamination, Thermal Air Treatment, humidification and dehumidification.

To speak with us about our air handling units: +49 711 8804 8000

Makeup Air Handling Units

Make-up Air Handling Units are custom-designed and custom-made units for the conditioning of outside air to become suitable for the respective application in respect to temperature, humidity and cleanliness.

Supply & Return AHUs

Recirculation Air Handling Units are custom-designed and custom-made units for the conditioning of recirculated air to become suitable for the respective application in respect to temperature and cleanliness.

Cleanroom

Superior solutions and comprehensive services

We develop, produce and maintain reliable cleanroom products and production environments for ultra-clean controlled atmospheres.

Mini Environments

In the battery market, Exentec pioneers a unique modular Mini Environment concept, integrating energy reduction and technological improvements.

Air Handling Units

Air Handling Units from Exentec are distinguished by energy-efficient design. Our research and development team works with state-of-the art equipment and always contributes the latest knowledge.

Critical Subsystems and Controlled Environments

Pure media supply systems for sensitive products

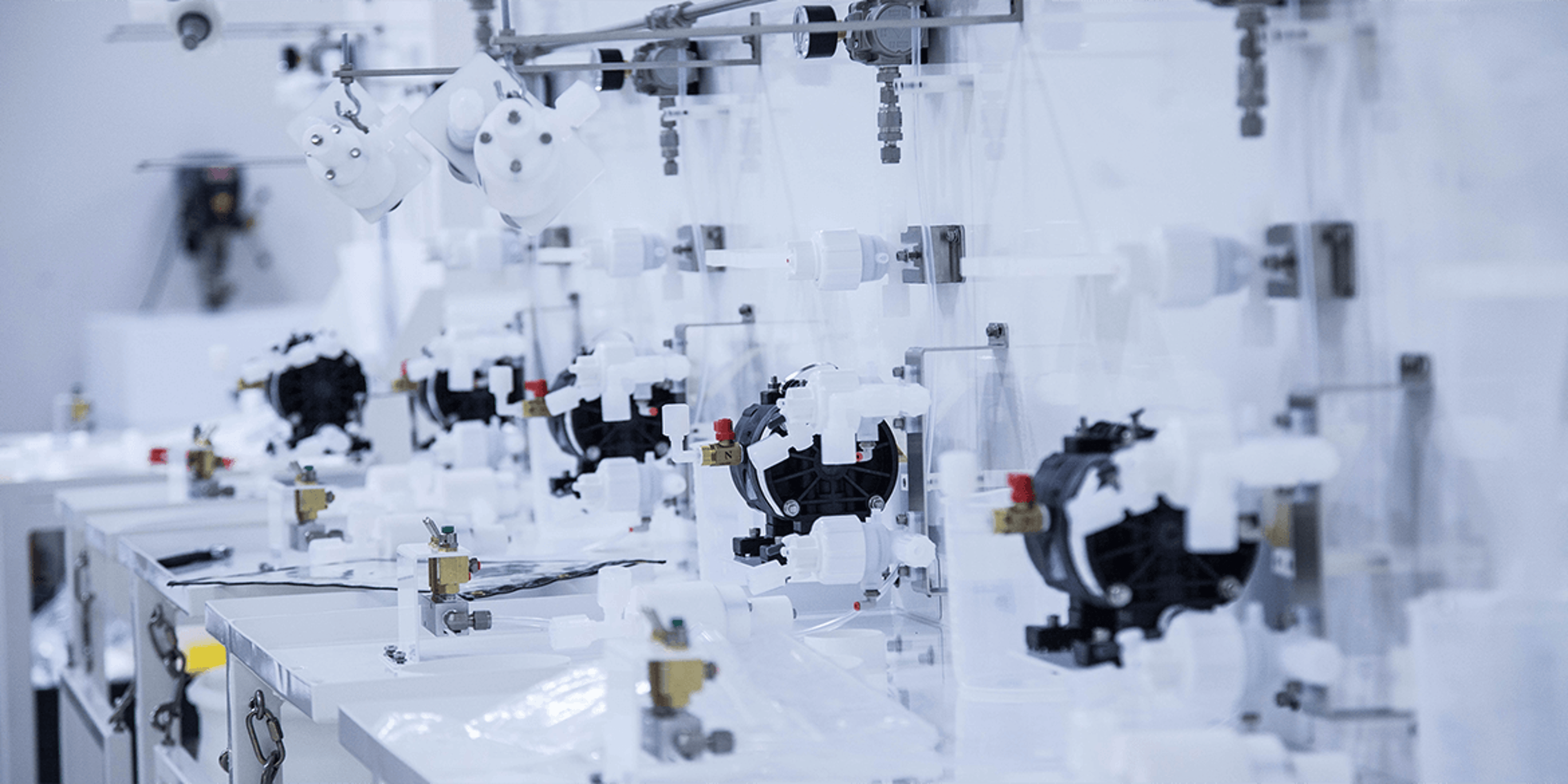

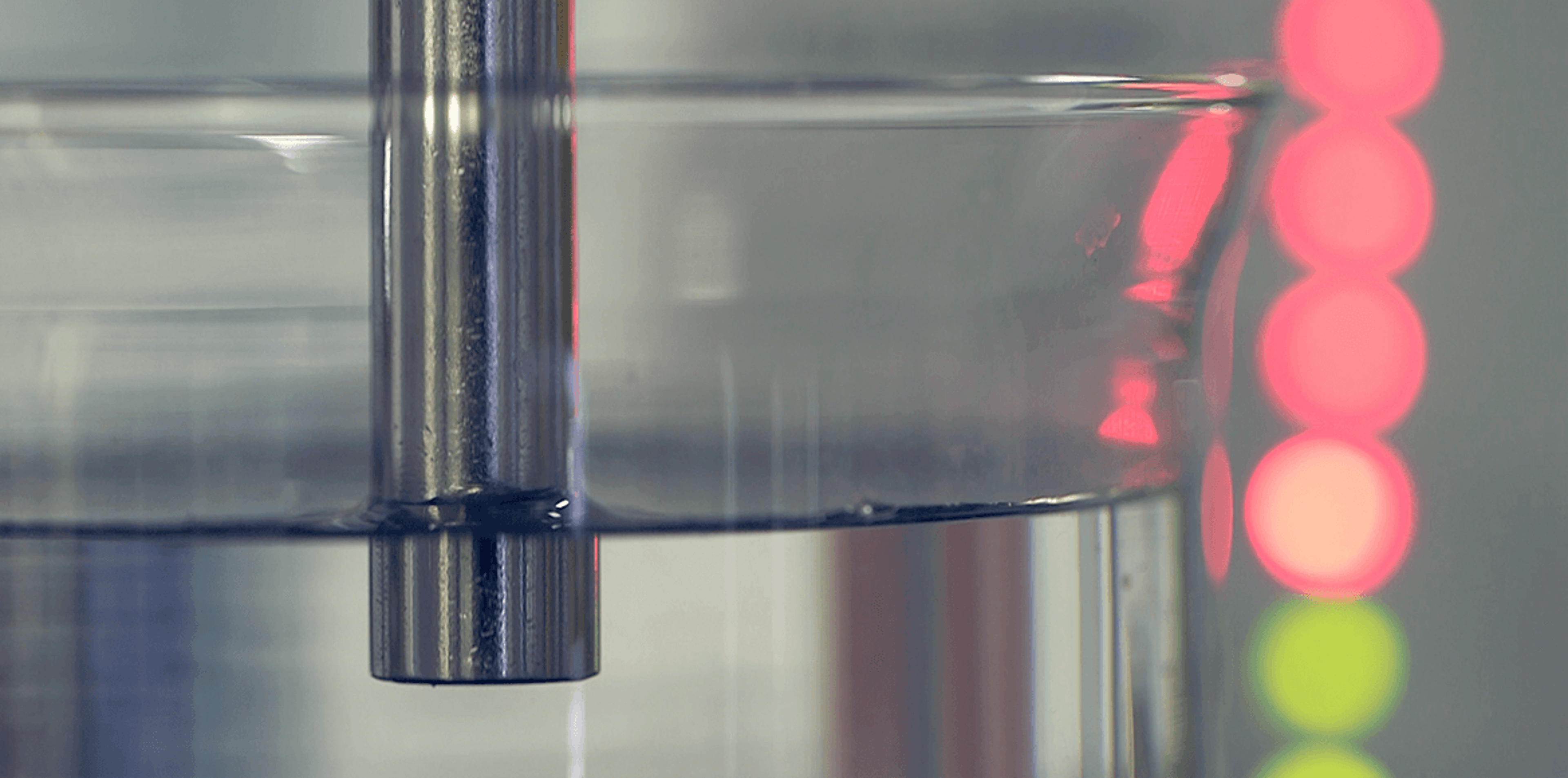

Chemical Supply

Ultra-high purity chemical & slurry blending and distribution systems

Ultra-high purity chemical & slurry blending and distribution systems

Ampoules and Sensors

We manufacture liquid level sensors, pyrophoric chemical handling and DOT 4B ampoules, cylinders and canisters widely used in the semiconductor, photovoltaic and battery industries.

Process Exhaust

We set the industry standard for safe and reliable corrosive fume exhaust duct systems

Gas Abatement

We are a supplier of choice for major semiconductor companies around the world, providing Point-of-Use (POU) gas abatement solutions for deposition, etch and diffusion process tools.

Wet Bench

Exentec's Wet Bench products seamlessly align application requirements with equipment performance. We specialize in designing surface preparation systems

Exentec's Wet Bench products seamlessly align application requirements with equipment performance. We specialize in designing surface preparation systems

Slurry Systems

Exentec Slurry Systems are trusted worldwide for their critical role in advanced chemical mechanical planarization (CMP) processes