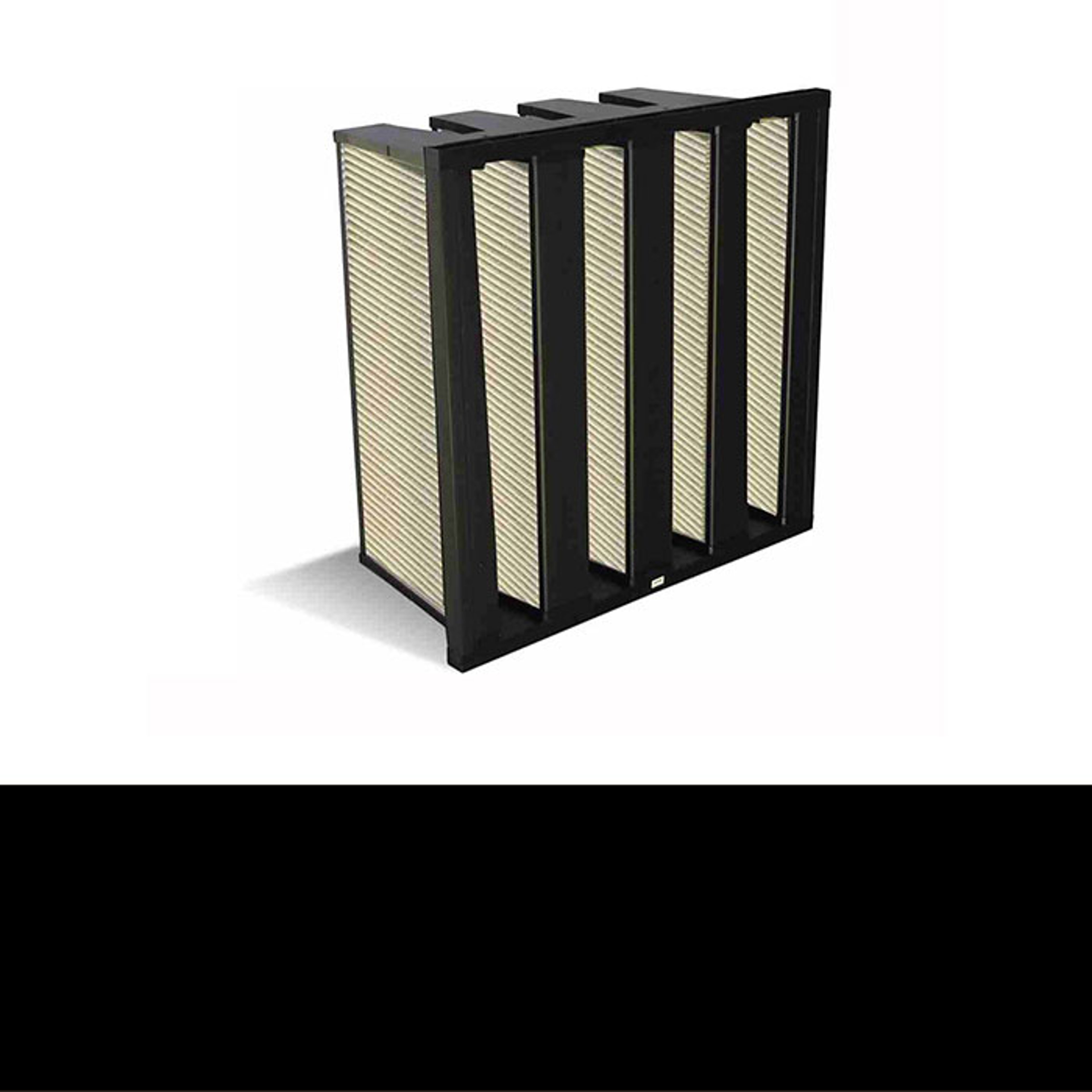

Exentec’s AMC Filters are engineered in our in-house technology center. They are each qualified and optimized in all relevant aspects such as filter capacity (max lifetime), highest removal efficiency (max process protection), lowest pressure drop (energy saving), lowest outgassing and particle development.

Why are AMC Filters important in cleanrooms?

Removing Airborne Molecular Contamination (AMC) is a special challenge in highly clean production environments (i.e. semiconductor manufacturing). Acids, bases, condensables and dopants in the process air can lead to undesired chemical reactions on the wafer surface and process equipment. Chemical filters are used in a wide variety of applications for the contamination control of ambient and circulating air. Exentec's AMC team offers a comprehensive service for testing and proofing chemical filter materials for the highest quality requirements. The development of filter materials is focused on removal of all acidic, basic and organic substances.

Classification of Airborne Molecular Contaminants

AMC compounds are typically classified in acids, bases, condensables (organic compounds with a molar weight of 120 g/mol and a boiling point of >150°C) and dopants (chemicals which can change the electrical properties of semiconductor wafers). There are also other substances, which are known to cause delirious effects (i.e. other corrosive species such as H2O2, H2S or ozone).

With ever shrinking device geometries of semiconductor chips, even low boiling VOC’s (volatile organic compounds) can be problematic. Exentec can consult with you and deliver a technical and economical solution for your process needs.