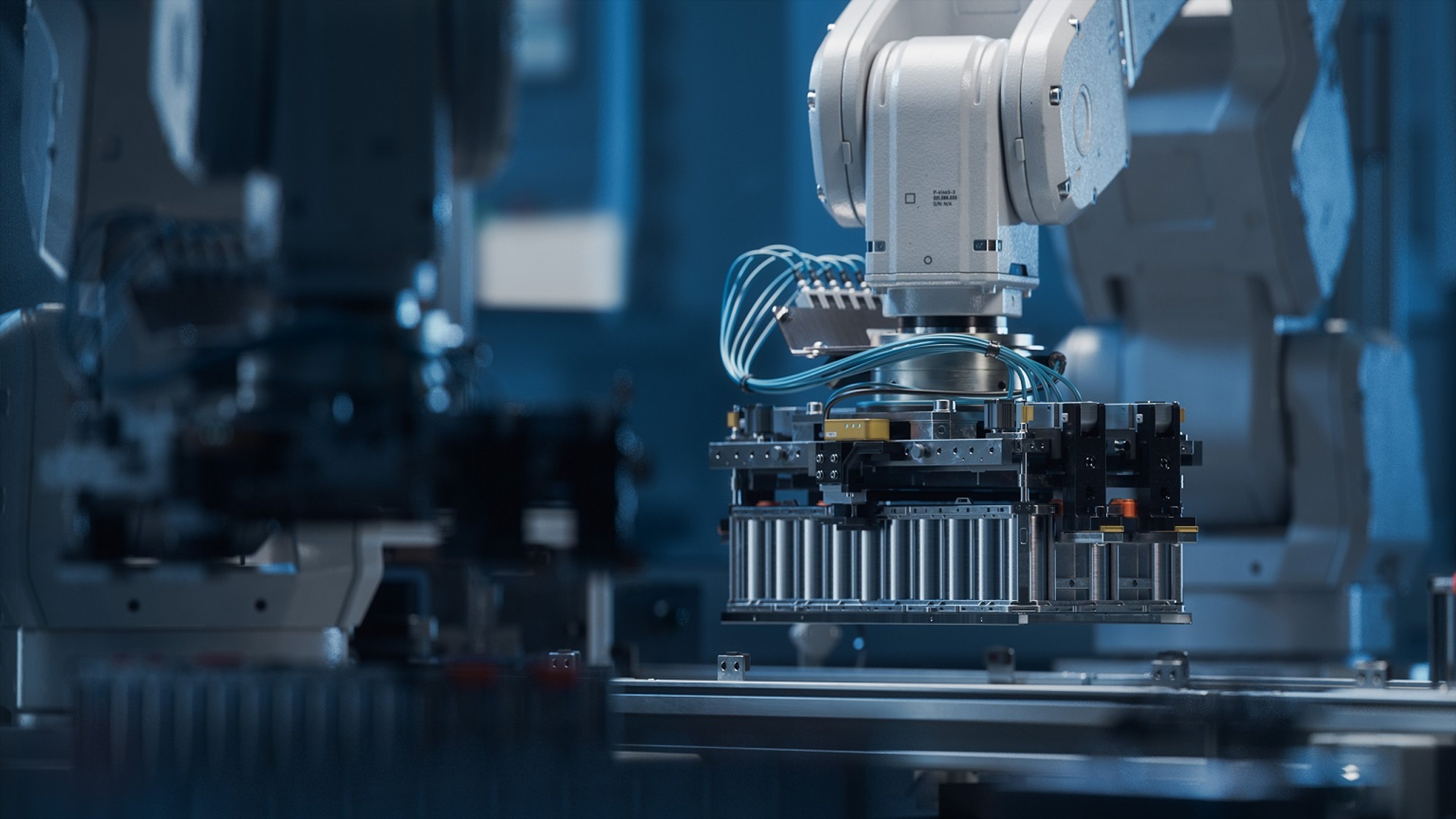

Controlled process, conditioned storage, consolidated manufacturing

Our battery market solutions provide advantages such as minimum energy demand, reduced OPEX, and a modular design that adapts quickly and flexibly to your needs.

Our battery market solutions provide advantages such as minimum energy demand, reduced OPEX, and a modular design that adapts quickly and flexibly to your needs.

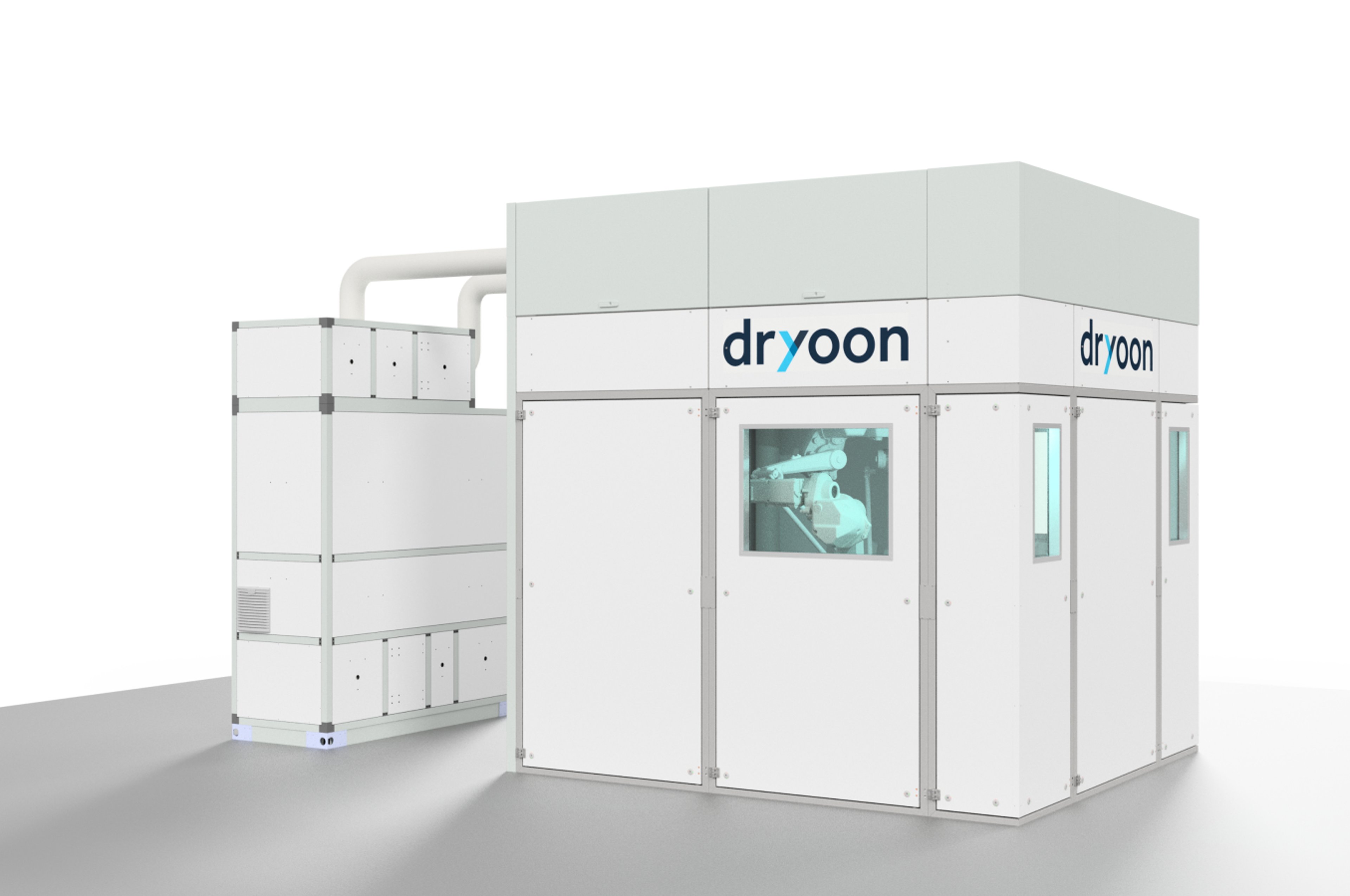

Controlled Environments

Optimized environments, including state-of-the-art dryrooms, are essential for safe and efficient lithium-ion battery production, from slurry preparation to storage. Exentec's patented dryroom concept reduces costs, while ensuring low humidity, constant temperature control, particle control for increased operator safety and special fire protection measures.