Unmatched performance for evolving R&D needs

Whether you're developing next-generation nodes or fine-tuning etch and clean recipes, the Aeris® Automated Wet Bench is designed to keep pace with innovation. From substrate cleaning to acid/base etching, this wet bench delivers. Applications:

- Process development

- Material evaluation

- Surface preparation

- Post-etch cleans

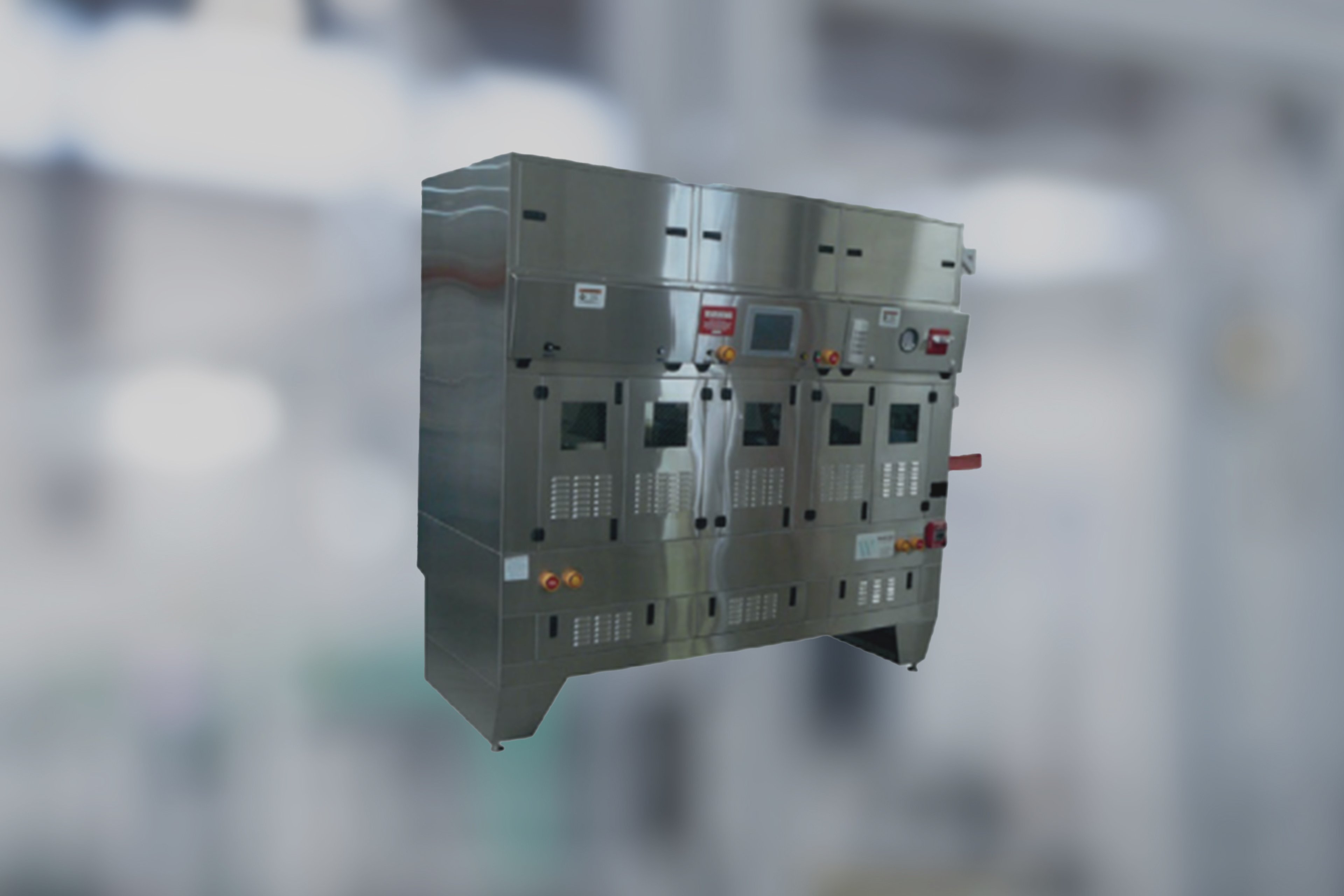

Available configurations include fully enclosed, semi-automated and customizable footprints to fit your lab layout and workflow.

The system's PC-based control interface enables continuous monitoring of wafer progress through the various process baths. This in turn maximizes overall wafer throughput by monitoring the complenathantion times of each process and automatically transporting the wafers through the successive baths. Each wafer lot is identified by a lot ID code and the process recipes are automatically downloaded to the CPU via the built-in Windows PC-based control system. The database and monitoring system can be connected to enterprise systems via a SECS II interface for real-time monitoring and data logging.

Aeris® Automated wet benches: For two or more process baths

Aeris wet bench automation is designed for processes with two or more process vessels. The transfer system can be set up either as a linear front-to-back or left-to-right configuration or as a 3-axis system allowing for more complex transfer between baths in a smaller footprint. Transfer systems are designed to accommodate single or dual wafer cassettes up to 200mm or a single 300mm wafer cassette. The control system includes a PLC and color touch screen interface (HMI). The PLC has multi-level password protection and can store multiple process recipes while the HMI has multiple screens for maintenance, recipe setup, tank setup, operation and alarm status.

The system at a glance: highlighted features

- Flexible configurations to support any wet chemical application

- Supports both single-wafer and batch processing

- 100mm to 300mm wafers plus custom substrates

- Linear or multi-axis robot configurations

- Multiple load / unload configurations

- Open or fully enclosed environment options

- Bath Recirculation / Filtration

- Heated, Chilled or Ambient Applications

- Megasonic and/or ultrasonic tanks

- Chemical Monitoring / Metrology Options

- Concentration, Conductivity, pH, Temperature, Particle Count etc.

- Bulk distribution or on-board dispense

- Bath spiking - Hydrogen peroxide, D.I. water & Additional Additives

- Surface tension gradient drying

- miSCADA controls – Integrates PLCs, Modbus, OPC/OPC UA servers, MQTT, and SECS/GEM

Options

- FM 4910 approved building materials.

- FM approved CO2 fire detection and suppression system

- SEMI and CE Marking or other NRTL third party testing and certification

- HEPA/ULPA air filtration

- Lighting device

- Windows-based PC with networking options

- SECS/GEM or asset management type software available